SmartComb identifies critical load combinations and calculates maximum and minimum force envelopes for structural members. By using an intelligent algorithm, it eliminates unnecessary combinations and significantly reduces engineering time by minimizing excessive post-processing.

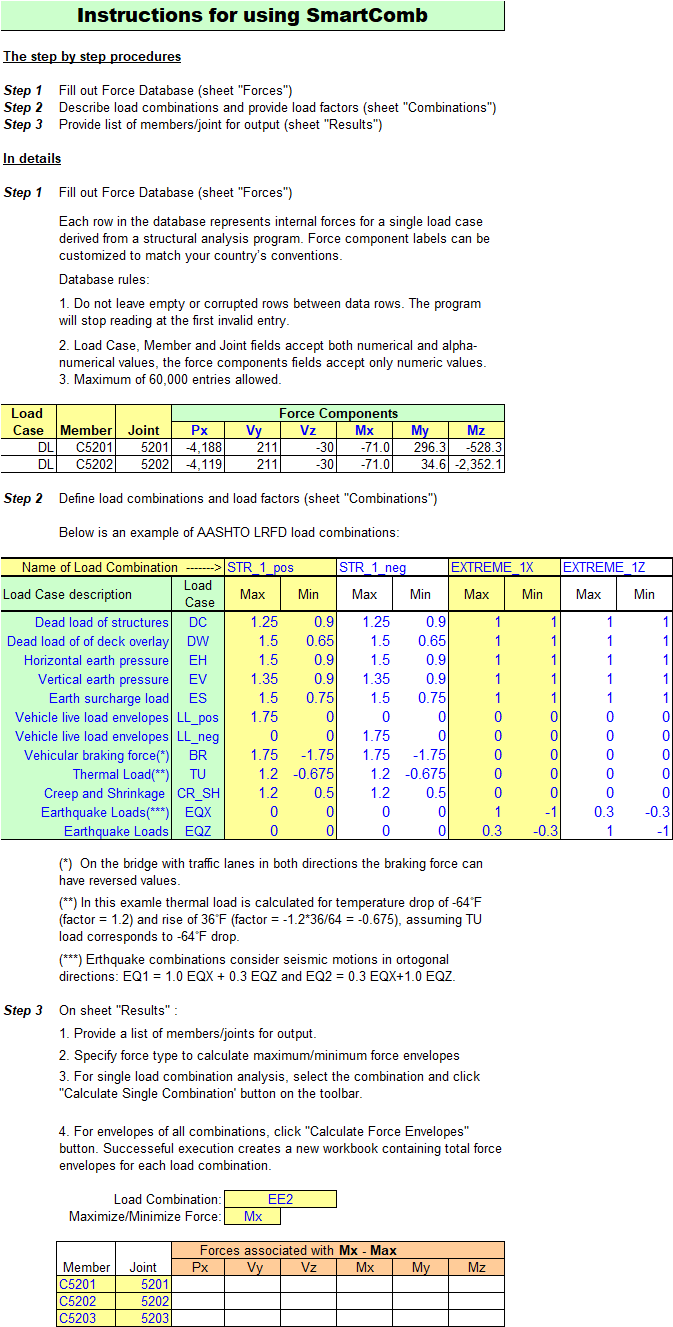

Most design codes require two load factors—one for magnifying and one for reducing—in the same combination. For example:

| Load Case | Maximum Factor | Minimum Factor |

| Dead Load | 1.25 | 0.90 |

| Active Earth Pressure | 1.50 | 0.90 |

| Vehicle Load | 1.75 | 0.00 |

| Earthquake Load | 1.00 | -1.00 |

When a combination includes four individual load cases, the number of sub-combinations to consider is 2⁴ = 16. For eight load cases, this grows to 2⁸ = 256. Engineers often apply logic to limit the number of combinations in structural analysis software and request maximum and minimum force envelopes. However, in complex models, it is difficult to determine which sub-combinations can be safely disregarded. This uncertainty can lead to missed critical values and challenges in obtaining associated forces, such as axial force corresponding to maximum bending moment.

The SmartComb spreadsheet provides an elegant and efficient solution to this problem. It determines maximum and minimum forces while tracking associated forces without generating the large datasets required by conventional methods. The only input data needed are member forces from individual load cases and a description of load combinations with dual factors.